High Performance Submersible Motors

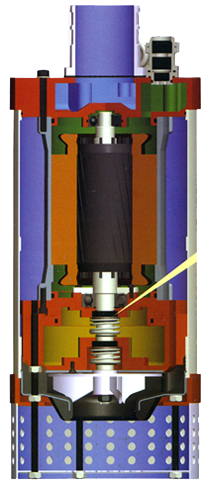

All KPR' S dewatering pumps are equipped with a heavy duty class 'F' insulated submersible motor with shrink fitted stator for exceptional heat transfer, keeping the motor cool even under snore or partial submergence conditions. Motor windings are dipped & baked three times in high temperature class 'H' insulating varnish for extended protection against. burnout & moisture penetration. The entire motor operates in air, reducing motor drag while eliminating the possibility of environmental contaminations.

Corrosion

All KPR'S impellers are design to keep working under extremely harsh conditions. They are produced in stainless steel 410 grade and machined in our own machine shop to exacting specifications and finished to very high hardness levels. Hardness reduces

Heavy Duty Castings For Last Long

All KPR'S pump models are constructed of strong die cast aluminum top cover & bottom cover with sand blasted and epoxy coated for last long.

Long Life Seals

All models use an exclusive dual tandem, double mechanical seal system, with each set mechanically independent, for added protection against water intrusion. Seal faces are tungsten carbide. for maximum resistance to corrosion, abrasion & thermal shock. The seals are operated in a stainless steel chamber filled with lubricating oil.

Wear Resistant Steel Oil Chamber

All KPR' S pumps are equipped with constructed of strong investment cast stainless steel seal housing for continues seal lubrication and long life.